PROFIBUS DP is the main emphasis for factory automation, it uses RS-485 transmission technology. DP is the simple, fast, cyclic and deterministic process data exchange between a bus master and the assigned slave devices. The original version, designated DP-V0, has been expanded to include version DP-V1, offering acyclic data exchange between master and slave. A further version DP-V2 is also available, which provides for direct slave to slave communication with an isochronous bus cycle.

Class 1 Master

- A central programmable controller (PLC)

- Exchanges I/O data with connected slaves

- Determines the baud rate (slaves auto-detect this rate)

- Manages the token transfer between masters. Detects another master during the gap time

Class 2 Master

- Diagnostic, configuration, or startup tool (laptop、PC、programming console)

- Can only control one slave at a time

- Does not have write-access to the slave

- Does not have a GSD file

Slave

- A passive station which can only respond per a master request and acknowledge messages. A slave has no bus control rights

- The GSD file defines the slave for the master

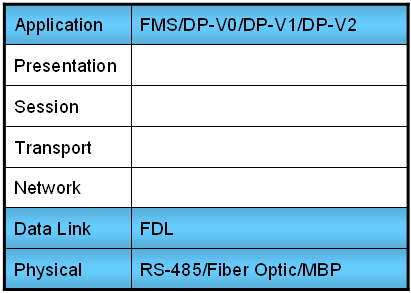

OSI Model

GSD

GSD is a readable ASCII text file and contains both general and device-specific specifications for communication. Each of the entries describes a feature that is supported by a device. A configuration tool reads the device identification, the adjustable parameters, the corresponding data type and the permitted limit value for the configuration of the device from GSD.

|